-

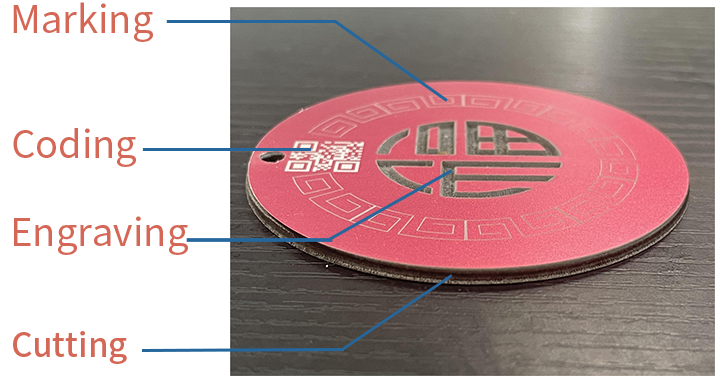

Cutting, Engraving, Coding Marking in 1 step!

-

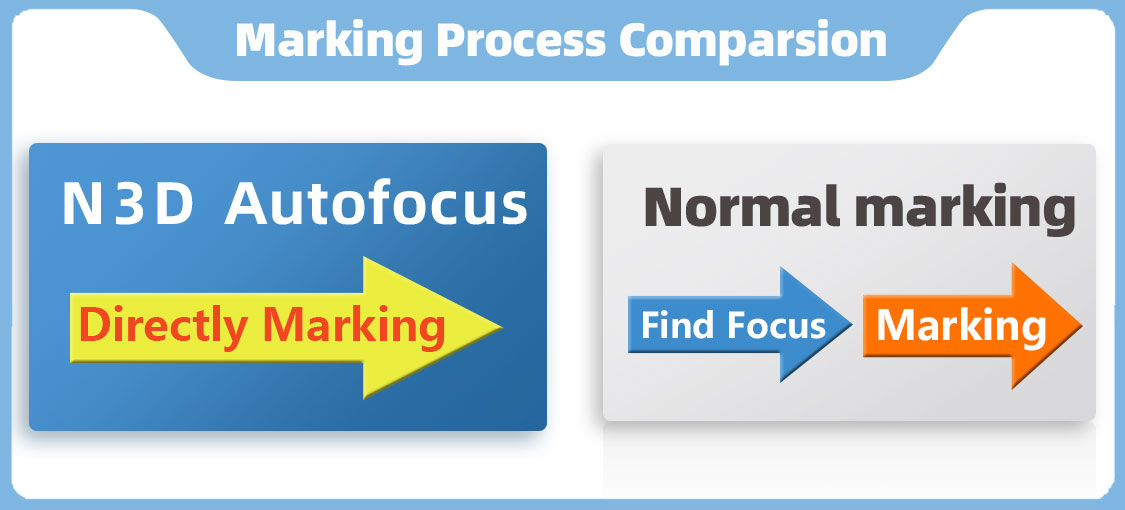

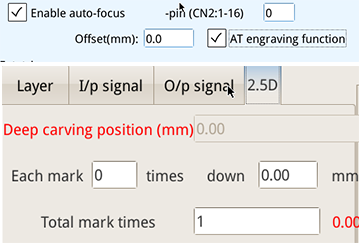

Breakthrough 1

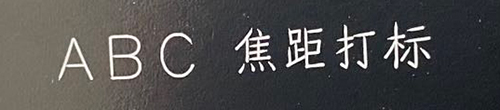

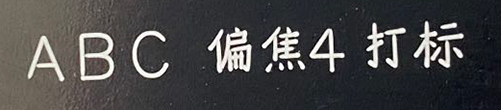

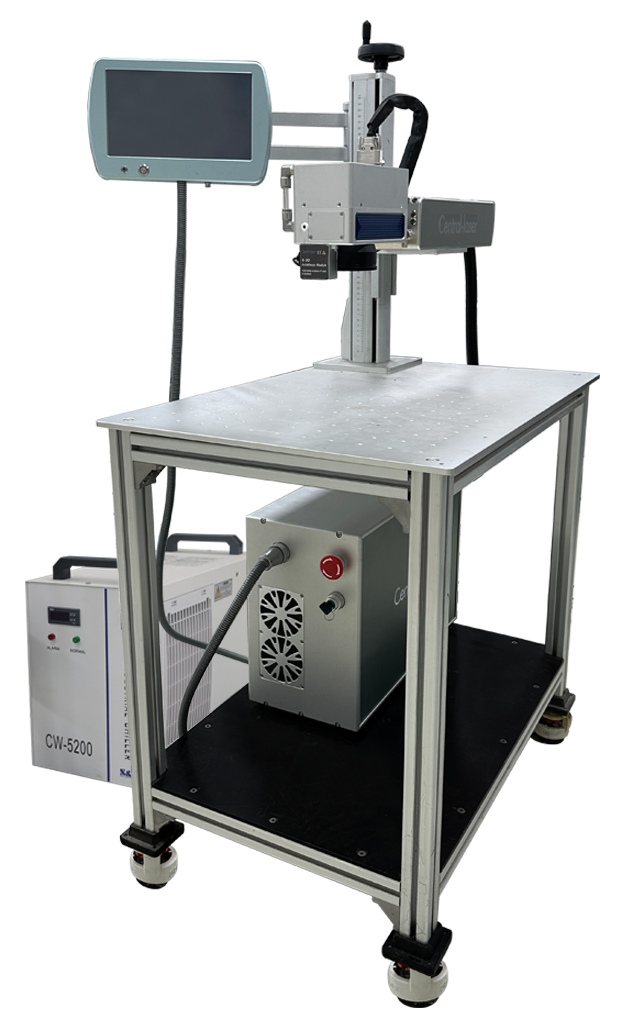

Breakthrough 1- No need to find focal length

With autofocus ,it can detect object’s height and don’t need to change height of scanner or object. It can adjust focal length automatically.

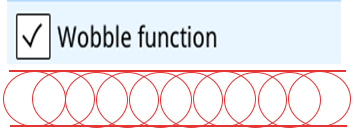

Breakthrough 2

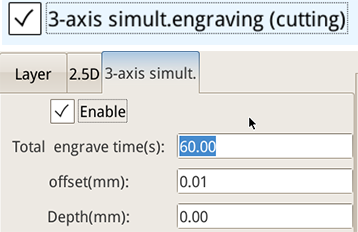

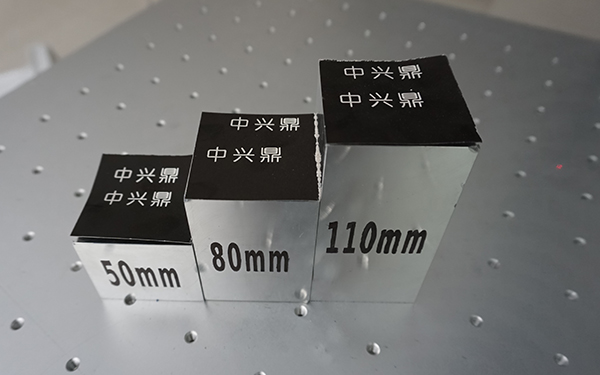

Breakthrough 2- 3D Cutting and engraving

Using forced water-cooling 3D scanner,coperate with spiral line ,make cutting and engraving more efficient, faster and have longer working hour.

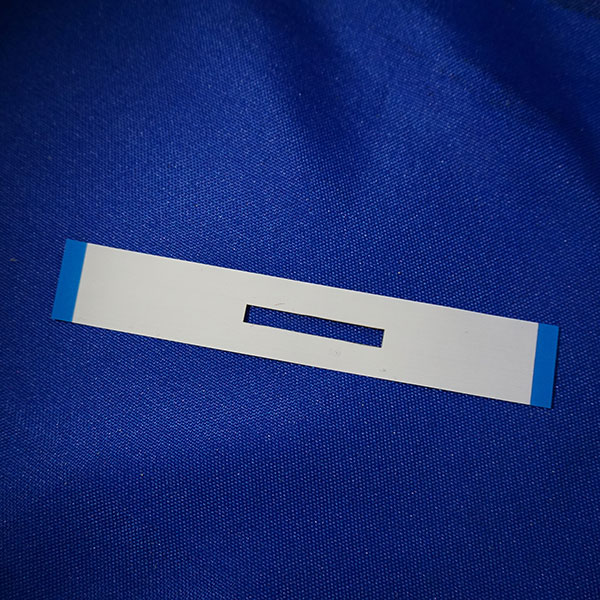

Material :AluminumDeepth :2mm

Material :AluminumDeepth :2mmProcess Description: Perform deep carving of the "福" character, contour and small circular cutting and mark the surface with patterns and QR codes on aluminum