Choose us

The company has accumulated many years of experience, we have the laser marking control system (software, board card), laser vibration lens, marking machine shell and lifting platform design and production capacity. It is not a general assembly and sales manufacturer of purchased components.

NMC-S2 embedded laser marking control system developed by ourselves has been highly evaluated in the current laser flight marking market. It can meet 90% of the application requirements of laser flight marking, and the system has anti-surge and power outage backup functions. NMC-S2 embedded laser marking control system, which can be used in extremely harsh and complex environment, has almost the same efficiency and function as the international mainstream products, and has been highly evaluated in the current laser flight marking market. It can meet 90% of the application requirements of laser flight marking, and the system has anti-surge and power outage backup functions. It can be used in extremely harsh and complex environment, and its efficiency and function are almost the same as international mainstream products

More than 5 years of experience in the development and design of vibrator, with a unique appearance design on the S-class products, and has a high marking accuracy and working stability; And provide customers with precision lens correction files, to ensure the accuracy of marking

All the components and accessories (chassis, optical frame, lifting platform, rotating shaft, etc.) are designed and manufactured by ourselves, which can ensure the highest quality of the whole machine and provide customized services quickly

We have the ability to develop the ARM control motherboard and application system by ourselves, and have developed the operating system under this platform:

1. Universal laser controller

2. conveyor belt fixed speed controller

3. NMC-S marking control system

4. Laser automatic desoldering of electronic components

5. Laser automatic 2D code marking detection system

Years of sales and counseling customers to use MarkingMate laser marking software system, practical experience accumulated in different laser marking environments and application requirements.

In the production, the raw materials purchased: electrical appliances, parts and components are implemented in accordance with IQC operation standards, and the factory parts are used in accordance with the safety regulations. Modular process production management, make product assembly and maintenance more simple and effective, all finished products need to be strictly burned, and cooperate with the actual instrument test qualified factory.

Standardized fixture testing is adopted for all original components as soon as they enter the factory, and strict burn-in testing is carried out for a long time. The testing process is rigorous and standardized.

The whole machine modular production, by professional technical personnel to carry out high-precision inspection :(1) continuous standard burning machine 72 hours; (2) Provide the final burner power output test sheet; (3) Lens precision correction table; (4) Complete product inspection form

The control system is assembled according to the standard assembly process and is debugged by professional technicians. After completion, enter the whole day 72 hours uninterrupted burning machine testing, to ensure that the products after shipment, long time use without any quality problems

The company has always followed the 5S operation standard for the assembly of laser marking machine. All the assembled parts are quality inspection. The parts that are qualified for acceptance are installed and inspected in accordance with the standard procedures to ensure that each product can meet the highest quality requirements before leaving the factory

Technical personnel for professional technical testing, and provide customers with precision lens correction files, to ensure the accuracy of marking

The whole machine products and high speed scanning vibroscope have the CE certification of European Union

In addition to the power supply, electrical connector, laser outsourcing, laser marking control card, software, high-speed scanning vibrator, product casing, lifting column and so on are all designed and produced by our own. We have the ability to provide products with the highest CP value. And have the ability to provide customers with customized functional products.

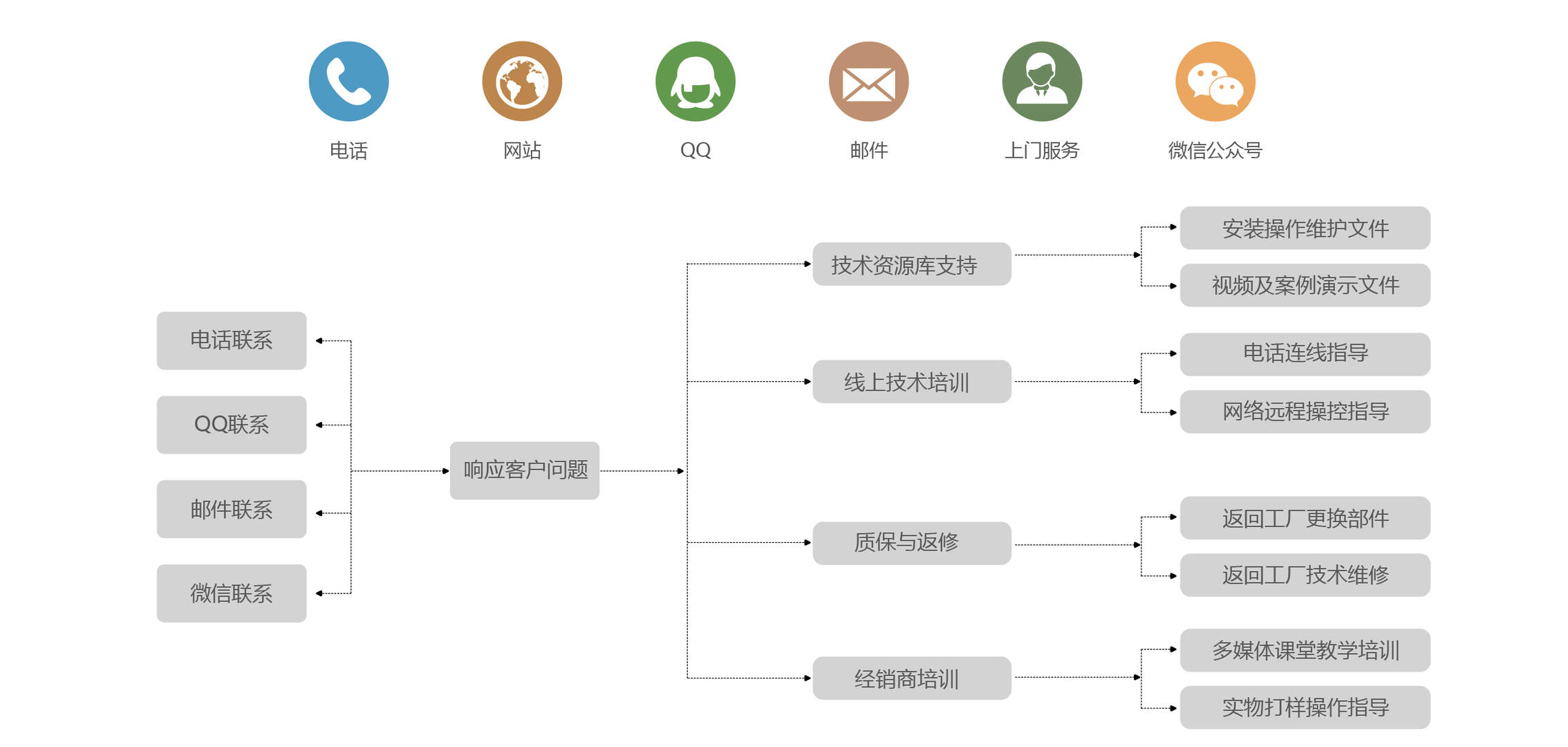

Our company has been adhering to all customer-centered service spirit, and strive to improve customer satisfaction. Gradually become the best choice in the hearts of customers, assured choice, the choice of trust. Always take customer value as the orientation, provide value-added services for customers, and finally achieve a win-win situation.

The company promises: "all our products from the delivery date, free warranty for 12 months"Provide free return to the factory for maintenance within the warranty period; Within and outside the warranty period, the company provides technical support and documents and videos of complete operation and maintenance steps.

The company provides the product quality inspection certificate (from the original factory and new products).

Provide two-year warranty certificate of return to the factory, where our products from the factory 12 months, if the product problems, we can enjoy the replacement and maintenance services

The company provides perfect manuals for installation, operation and maintenance of all kinds of products for customers to download and use

Provide relevant case data demonstration video files, so that customers can learn to operate

Every month in the company, regularly provide multimedia teaching for distributors, and physical operation training

The case of the whole product is made of light aluminum material, light weight, and it is convenient for express transportation with the packing box. Can be the fastest time and the most cost to complete product maintenance services

Our service tenet is "fast, decisive, accurate, thoughtful and thorough"

Our service tenet is "fast, decisive, accurate, thoughtful and thorough"

The company promises to respond to customer problems within 8 hours and provide online service platform within 12 hours. Follow up customer issues 1 by 1 and provide corresponding solutions. In the later stage, the technical staff of the company will make a return visit to the customer's telephone satisfaction from time to time. If you have any other complaints, please call 0512-66359058.