-

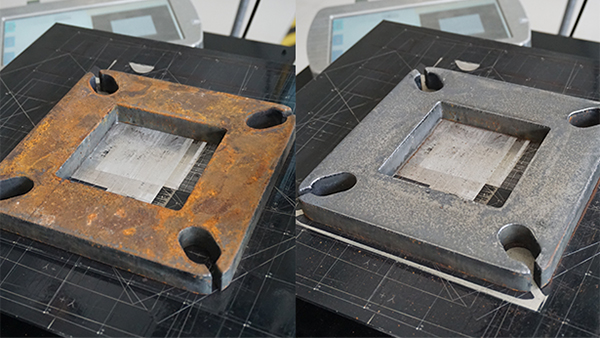

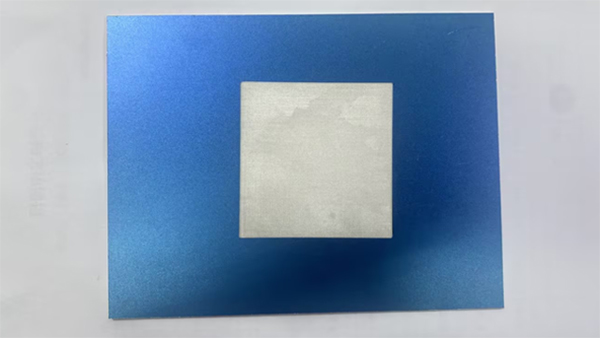

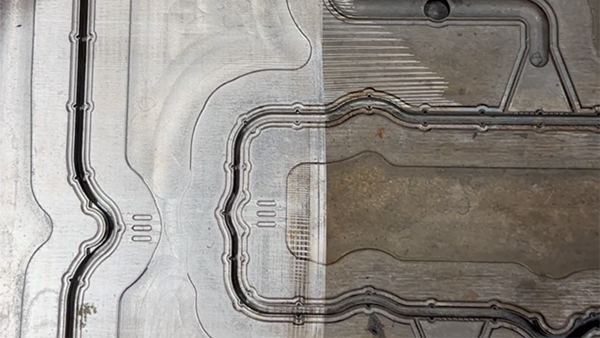

Laser Cleaning

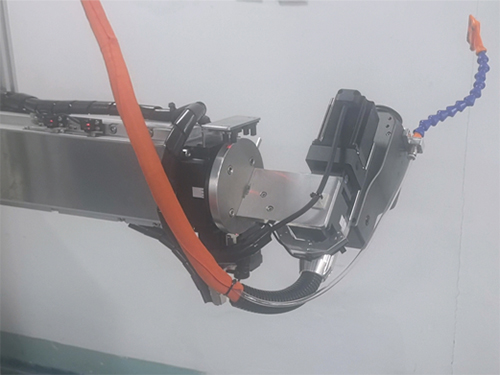

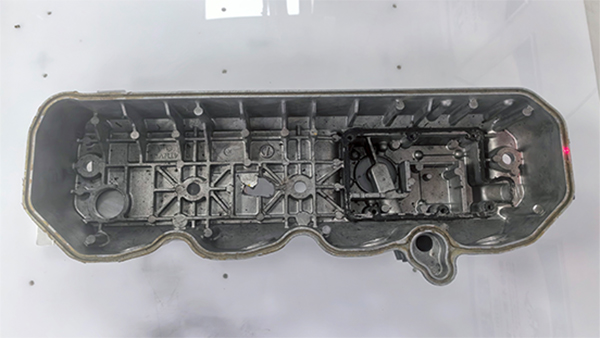

- Can clean Stereoscopic workpiece form any angle

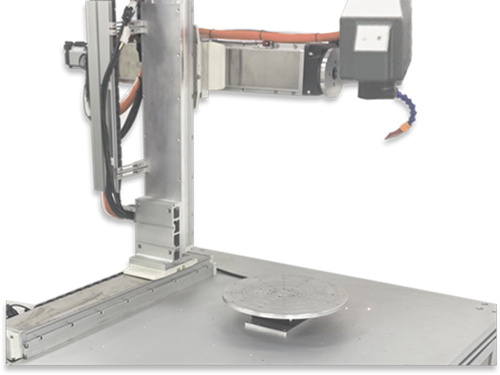

- Support static clean on specific area with multiple parameters

-

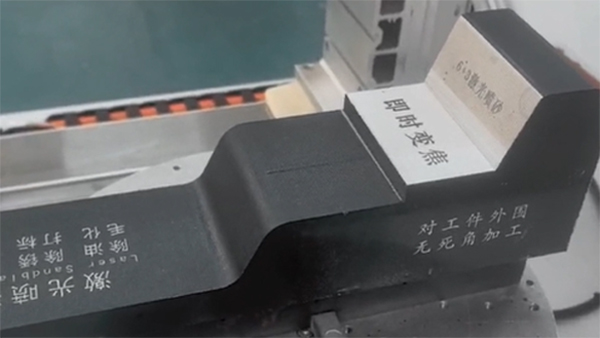

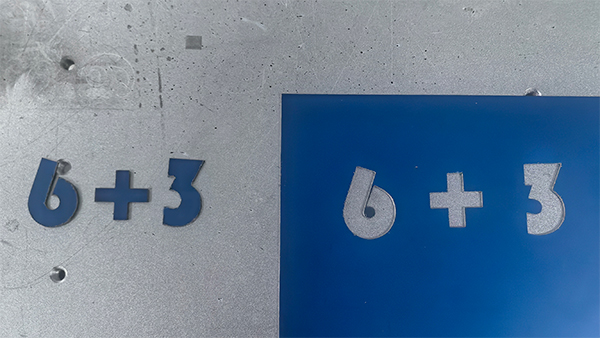

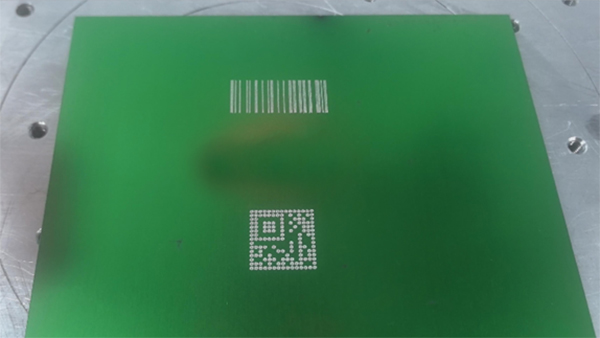

Laser Marking

- Can mark Stereoscopic workpiece form any angle

- Can move to specific areas to mark

Don’t need 3D model、can perform automatic process

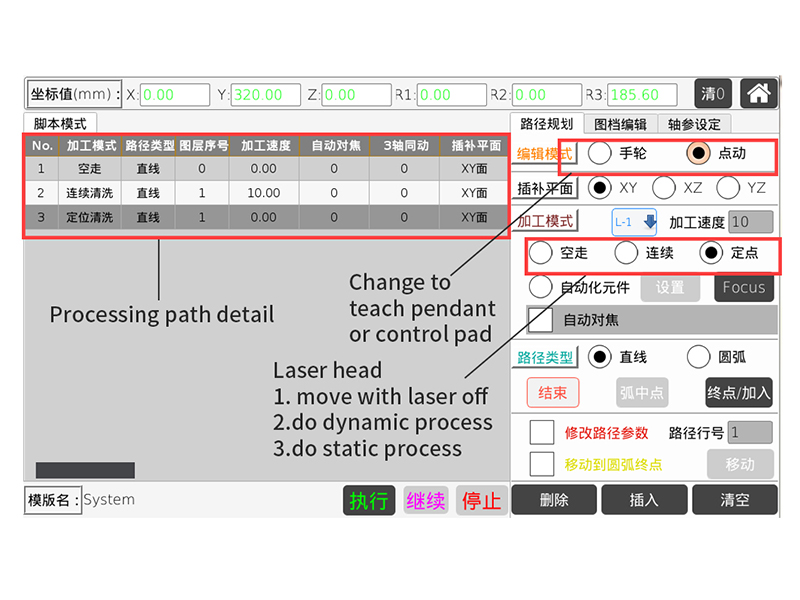

Move laser head and edit the machining path through Teaching Deconstration. Control teaching pendant or touch screen to simulate machining path. After editting the path, can directly perform automated process

Touch Screen

Touch Screen Teaching pendant

Teaching pendantCan move laser head to workpiece any position and angle

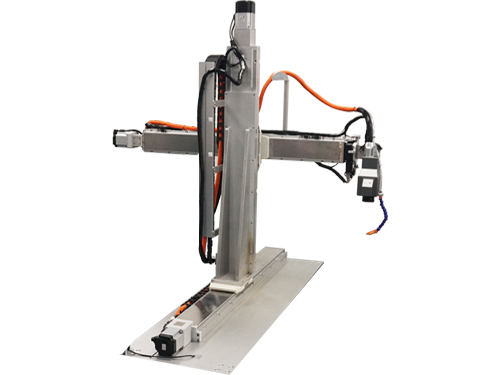

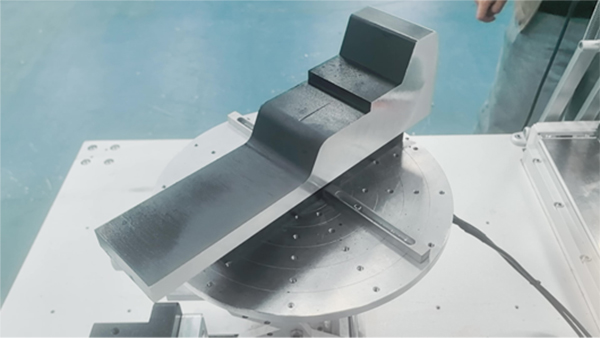

Coperate with Teaching Demonstration, control X、Y、Z axes, glavo front-back rotate, glavo left-right rotate, rotate disc for workpiece.

XYZ axes move

XYZ axes move Front-back rotate

Front-back rotate Left-right rotate

Left-right rotate Workpiece rotate disc (optional)

Workpiece rotate disc (optional)Control laser marking and cleaning accuracy through motion axes and laser head Make sure process area won’t shifting, accuracy can up to ±0.01mm.

Laser Head & Workpiece fixed to clean/mark

Laser head/workpiece move while cleaning

Can control laser and motion axes around workpiece to clean

Can set parameter for each clean to perform repetitive clean

Can copy machining path and move to specific area for same path clean

Control motion axes and laser head to clean according to the shape of workpiece

Move laser head and motion axes to clean around stereoscopic workpieces

Edit machining path by teaching demonstaration and perform automated clean

Move laser head and motion axes to project laser into the hole to clean automatically

Can mark Stereoscopic workpiece form any angle

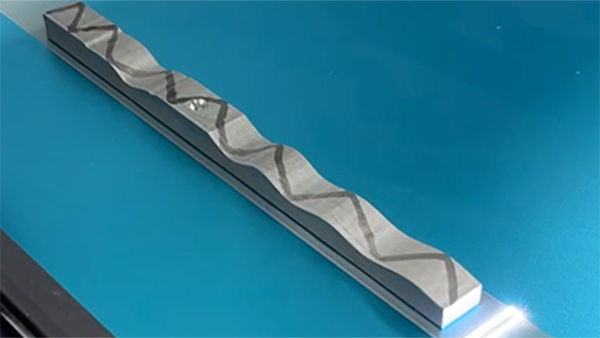

Can perform repetitive process to roughen the surface

Control motion axes X,Y,Z move to engrave workpieces horizontally and vertically

Control motion axes X,Y,Z move to cut workpieces horizontally and vertically

Support all kind of codes