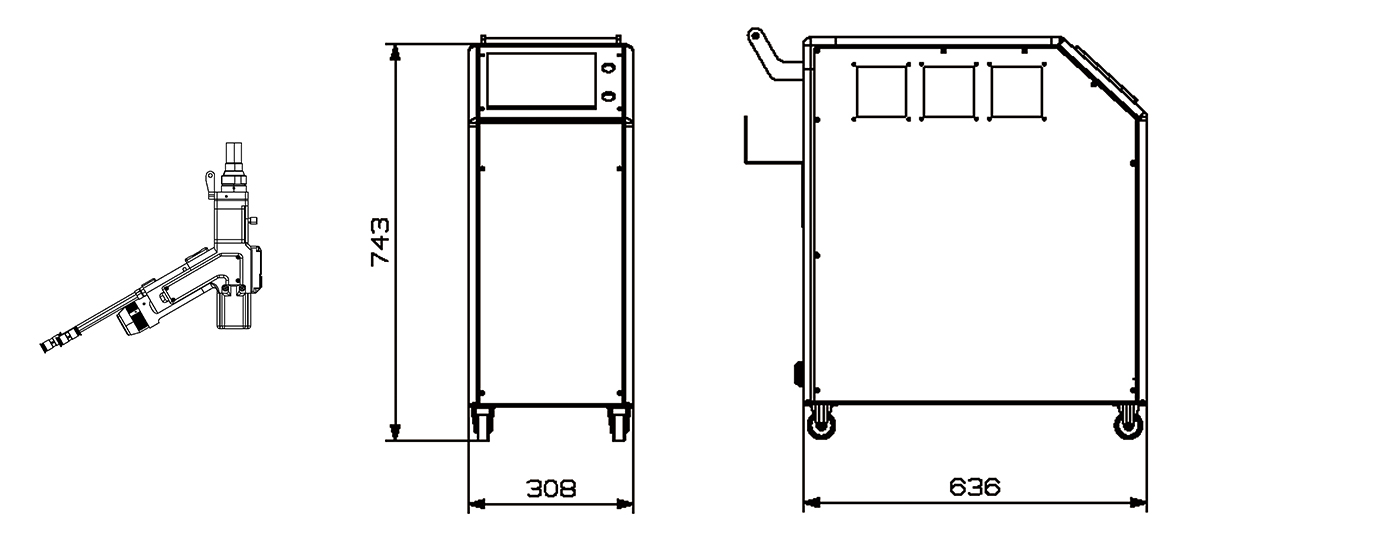

Control of laser working tempture is preciser. More power-saving and safer!

-

Refrigerant Direct Cooling

- Small noise

- Power-saving

- Strong temperature control(Most Advanced technology,>10000W)

- Small volume

- Strong stability

- Safer(No-water Operation)

-

Air Cooling

- Noisy(high speed fan)

- Power-saving

- Poor temperature control(Low Heat Exchange Capacity)

- Medium size

- Weak stability(dust,wroking temperature)

- Safe(No-water Operation)

-

Water Cooling

- Noisy(circulating water pump)

- Power-wasting

- Strong temperature control

- Large volume

- Weak stability(accumulate scale and electricity safety issues easily)

- Low safety(accumulate scale and electricity safety issues easily)